Rethinking bioplastics in the REFRAME project

What are PHAs?

What are PHAs?

Polyhydroxyalkanoates (PHAs) are bioplastics synthesized and stored intracellularly by a wide range of bacteria and archaea as a reserve of carbon and energy. PHAs are typically produced through microbial fermentation, where bacteria such as Cupriavidus necator convert carbon-rich substrates —such as volatile fatty acids (VFAs)— into intracellular granules of biopolymer.

A promising alternative to plastics

Over the past decades, PHAs have gained significant attention as biodegradable, bio-based, and biocompatible alternatives to fossil-based plastics, with potential applications spanning from packaging to biomedical devices.

The extraction challenge

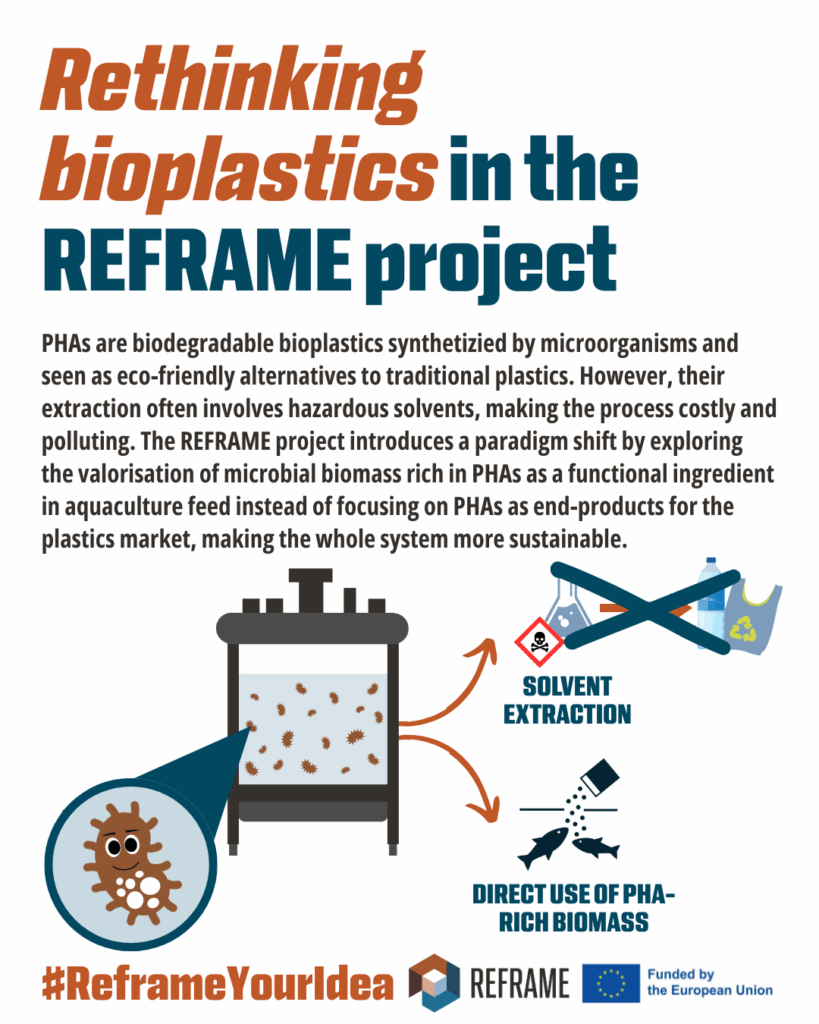

However, one of the main barriers to their widespread adoption is their extraction and purification process, which is energy-intensive, often requires hazardous solvents, and significantly compromises their environmental footprint. Ironically, while PHAs are positioned as a green alternative, their conventional recovery methods are anything but circular.

The new perspective of REFRAME project

This is where the REFRAME project, funded by the European Union, introduces a paradigm shift.

Instead of focusing on PHAs as end-products for the plastics market, REFRAME explores the valorisation of microbial biomass naturally rich in PHAs as a functional ingredient in aquaculture feed. This approach circumvents the need for costly and polluting extraction steps and opens the door to new value chains based on microbial proteins (MPs) enriched with biopolymers.

Why is this important?

- 🐟 Healthier aquaculture: PHAs exhibit prebiotic and probiotic properties when ingested by aquatic animals. Once degraded in the gut, they release short-chain β-hydroxy acids, which exhibit bacteriostatic effects and promote gut health. Experimental studies with zebrafish (Danio rerio) fed diets enriched with microbial biomass containing PHAs showed improved survival rates and growth performance compared to conventional fishmeal-based feeds.

- 🌊 Reducing fishmeal dependency: the use of MP-based feed ingredients supports the transition away from fishmeal, which is increasingly unsustainable due to overfishing and ecosystem stress.

- ♻️ Integrating with waste systems: combining MP production into existing anaerobic digestion (AD) infrastructure allows us to build biorefinery models that recover energy (biogas) and bio-based materials (proteins, VFAs, PHAs) from a single waste stream.

REFRAME’s approach highlights the strategic potential of waste-derived microbial biomass, for example, converting cellulose from toilet paper in urban wastewater into MPs/PHA with functional benefits. This is not just waste valorisation; it is systems innovation that touches on waste treatment, food production, environmental protection, and economic sustainability. We are trying to redefine how PHAs can serve beyond packaging, as tools for sustainable health feeds and close the loop in our bio-based economy.

Sources: Giovanna Pesante, Chiara Tesoriero, Emma Cadoria, Marco Andreolli, Silvia Lampis, Andrea Vettori, Nicola Frison, Valorisation of agricultural residues into Thauera sp. Sel9 microbial proteins for aquaculture, Environmental Technology & InnovationVolume36,2024; Giovanna Pesante, Anna Zuliani, Elena Cannone, Francesca Greco, Chiara Tesoriero, Andrea Vettori, Nicola Frison, Biological conversion of agricultural residues into microbial proteins for aquaculture using PHA-producing mixed microbial cultures, Journal of Cleaner Production, Volume 378, 2022; Giovanna Pesante, David Bolzonella, Aleksandra Jelic, Nicola Frison, Upgrading biogas plants to produce microbial proteins for aquaculture feed, Journal of Cleaner Production, Volume 459, 2024.

#ReframeYourIdea #PHAs #Aquaculture #Biorefinery #ScienceForEveryone

What are PHAs?

What are PHAs?