VFAs and circular economy

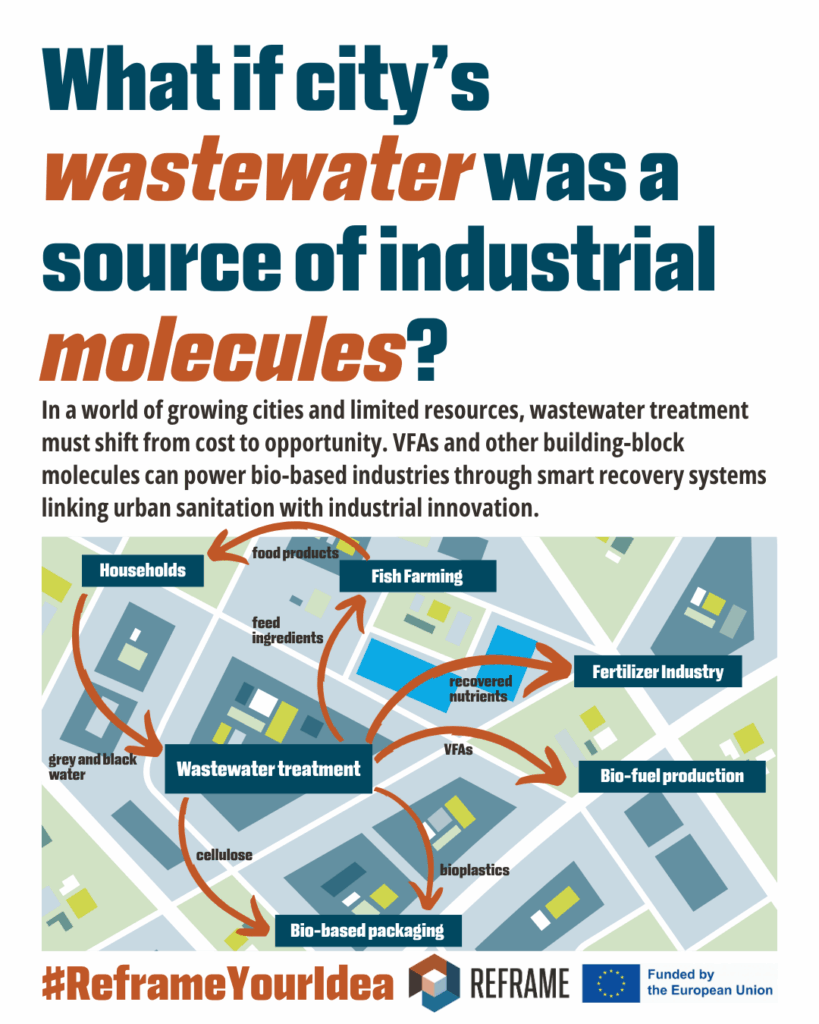

What if your city’s wastewater was a source of industrial molecules?

What if your city’s wastewater was a source of industrial molecules?

Let’s talk about VFAs – volatile fatty acids – and their potential to transform how we view sewage sludge and fermentation.

VFAs like acetate, propionate, and butyrate are short-chain organic acids that can be produced naturally through the fermentation of organic waste, thus avoiding dependence on fossil fuels. Instead of being fully digested into biogas, organic matter is stopped midway, maximizing the yield of these valuable molecules.

But VFAs are not just intermediates. They’re building blocks.

They can be used to produce:

- biofuels;

- platform chemicals.

And after further biological processes:

- biobased plastics and resins;

- animal feed ingredients;

- fertilizers.

Their value is orders of magnitude higher than traditional methane. The challenge? Making them cleanly and consistently from real waste.

A new role for wastewater systems

One of the most inspiring frameworks to come across is the Circular Amsterdam vision: a roadmap where wastewater treatment plants are integrated into the urban metabolism. This means:

- primary sludge becomes feedstock, not just a burden;

- VFAs can be harvested and fed into external value chains, not just confined to energy use;

- the boundaries between “urban sanitation” and “urban industry” start to blur.

The idea is not utopian, there are already quantifiable pathways and guidelines to make this happen. Several reports and pilot projects demonstrate resource recovery from wastewater is no longer theoretical.

But one barrier remains: the separation

To move from fermented sludge to usable VFAs, we need robust, scalable separation processes that:

- break the regulatory “waste/product” wall;

- produce high-purity acids from low-value feedstocks;

- allow entry into sensitive applications (like food, feed, or chemical synthesis).

Membranes, solvent extraction, and even in-situ recovery strategies are all making this feasible. With the right process, we can transform urban cellulose sludge into VFAs and then into bioplastic or animal feed ingredients.

Why it matters

In a world of growing cities and resource constraints, wastewater treatment must evolve from a cost center into a resource hub. And VFAs are one of the clearest, most versatile examples of this shift.

Wastewater is not an endpoint. We need to desig systems that interface with real industrial demand, outside the traditional water sector.

Source: Resource Recovery from Water: Principles and Application, Ilje Pikaar, Jeremy Guest, Ramon Ganigué, Paul Jensen, Korneel Rabaey, Thomas Seviour, John Trimmer, Olaf van der Kolk, Céline Vaneeckhaute, Willy Verstraete, IWA Publishing, 2022, https://doi.org/10.2166/9781780409566

#ReframeYourIdea #VFAs #CircularEconomy #ScienceForEveryone

What if your city’s wastewater was a source of industrial molecules?

What if your city’s wastewater was a source of industrial molecules?